A control valve is a device that controls, mixes, or closes

the process temperature, pressure, flow, etc. It is called a control valve. Or

process line variable restriction is called control valve. There are two main

and major types of control valves.

Control Valve

A control valve is a device that controls, mixes, or closes the process temperature, pressure, flow, etc. It is called a control valve. Or process line variable restriction is called control valve. There are two main and major types of control valves.

- Linear Motion Control Valve

- Rotary Motion control valve

Control Valve Parts

and Terminology

|

| Control Valve parts |

Diaphragm Case

It is considered the backbone of the control valve and is the

most important member of the control valve. It consists of the upper and lower

sections of the control valve. It is used to support the diaphragm.

Diaphragm Plates

This plate is attached to the diaphragm to transmit the

force to the equator.

Actuator Spring

It moves with the movement of the spring diaphragm. And it

works on the principle of resting force.

Spring Seat

It is a plate that holds the spring in position. And it

provides a smooth surface for contacting the spring adjuster.

Spring Adjuster

It usually has a wide fitting above the actuator stem or

inside the yoke. Which adjusts the compression of the spring.

Yoke

This is the part that connects the body of the actuator and

the control valve. Spring fits inside this yoke. Attached to the valve's travel

indicator and scale yoke.

Travel Indicator

It is a pointer attached to the stem connector. This

indicates travel with the valve plug.

Travel Indicator

Scale

This is a graduated scale that is attached to the yoke. And

it shows valve travel.

Packing Box

It is part of a bonnet assembly. According to the process,

glands are inserted in it which seal the stem from all sides and do not allow

the process to leak out of this path.

Bonnet

This part is mounted on the body of the control valve.

Cage

It is a cylindrical trim element. It guides the movement in

a straight line with the valve seal rings in the valve body.

Valve Plug

It is a moving part that provides variable restrictions in

the port.

Seat Ring

It is usually a round plate with a hole in the middle.

Actuator Stem

It is a rod that is attached between the diaphragm plate and

the valve plug and connects them.

Characteristics of

Control Valve

Much depends on the flow characteristics of the valve, the

design of the valve, and the trim material. That is, when the actuator receives

the signal, how much the control valve plug travels from its seat ring and how

much flow it keeps dropping? When the valve moves through the plug actuator,

the path to the flow is greater.

How many types of

Control Valves?

There are two types of control valves.

- Linear Motion Control Valves

- Rotary Motion Control valves

Generally, the following features are inherent to control flow.

Characteristics

- Linear Flow Characteristics

- Equal Percentage Flow Characteristics

- Quick Opening Flow Characteristics

Linear Flow Characteristics

The flow rate in the control, which has linear flow

characteristics, is directly proportional to the travel of the valve plug. For

example, if the valve plug travels 50%, the flow rate will be 50%. This type of

control valve is most commonly used where constant gain is required.

Equal Percentage Flow

Characteristics

In a control valve with this feature, when the wall plug

travels uniformly, the flow rate will change very little, that is when it is

close to the off position. Similarly, if the plug travels more, the flow rate

will also change a lot. That is, it will be close to the full ON position. For

example, if the plug travels from 20% to 30%, the flow rate will change from 4%

to 6%. And if the plug travels from 80% to 90%, the floor rate will change from

47% to 70%.

Quick Opening Flow

Characteristics

In the control with quick open flow features, the flow rate

changes as much as the valve plug travels very little. Conversely, if the valve

plug travels maximum, the flow rate changes very little. For example, if the

plug travels 110%, the floor rate will change by about 40%. And if the plug

travels from 80% to 90%, the flow rate changes from 77% to 95%.

Working Principle of

Control Valve

Pneumatic Actuator

Pneumatic actuators require air or signal to produce a

controlling process. The actuator takes the pneumatic signal force from its

upper part. It then divides this signal into diaphragms. And then the diaphragm

puts pressure on it. This is how the control valve gets stroked.

Devices that receive an electronic signal and run on a

motor.

The control valve is a device that operates automatically. It is

mostly used for pressure. The control valve operates with the help of a special

part called a valve plug. This part is connected to the stem. And the stem is

attached to the actuator.

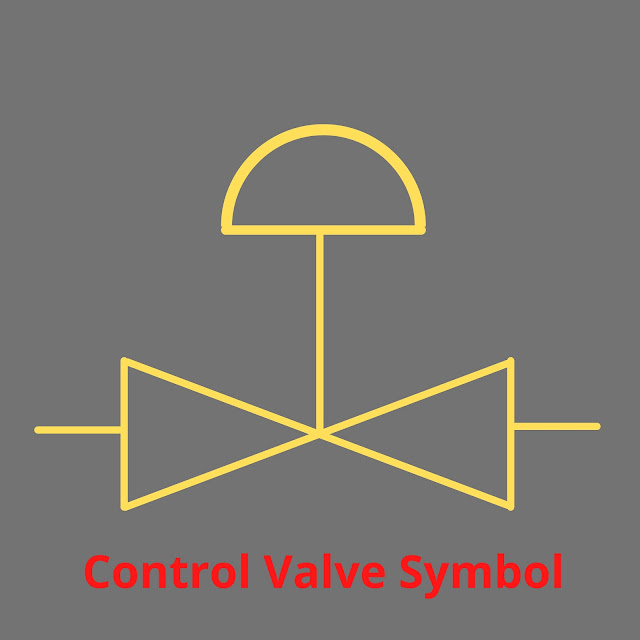

Symbol of Control Valve

|

| Control Valve Symbol |

- What is Control Valve

- Parts of Control Valve

- Types of Control Valve

- Characteristics of Control Valve

- Diagram of Control Valve

- Symbols of Control Valve

- Working Principle of Control Valve

Thanks For Reading.

Website: www.factsaboutworlda2z.website