This article covers Tachometers and all types of Tachometers. The use of Tachometers, working principle, and structure are also

explained in detail.

Tachometers

Tachometers are used to measure the rotational speed

(angular velocity) of motors, generators, and other rotating machines. These

are called tachometers. A tachometer is also called a speedometer or speed

counter.

Types of Tachometers

1. Mechanical Tachometers

2. Electrical Tachometers

- DC Generator Tachometers

- AC Generator Tachometers

- Induction Tachometers

- Eddy-Current Tachometers

- Drag Cup Tachometers

3. Electronic Tachometers

- Tooth Rotor tachometers

- Photo-Electric Tachometers

- Stroboscopic Tachometers

Mechanical Tachometers

Mechanical tachometers are used to count and collect the

number of cycles, instead of expressing the speed of a shaft in RPM, with the

help of various gears or wheels or drums, or special mechanical mechanisms. That

is why they are also called registers. A typical example of a mechanical

counter is the mechanical counter. This type of counter is also used in energy

meters, vehicle pedometers, and industry.

Working Principle

In mechanical counters, several gears, cogwheel wheels, or

solid toothed drums are attached in such a way that the movement of one wheel

moves the rest of the wheels in a certain proportion.

Construction

A toothed wheel type counter has three, four, or five wheels

with ten teeth. Each wheel or drum is numbered from 0 to 9. And these wheels

(or drums) are locked together in a case in such a way that only one digit of

it is on the harrow (or drum) in the window in front of the box. Is visible

from. Figure (a) shows a mechanical stroke type counter. It is also called a

Ratchet Type counter. With ten strokes, its unit drum (or wheel) completes one

cycle (0 to 9 digits).

|

| Tachometers |

Before one cycle of the unit drum is completed, the other

drum rotates up to one digit through a transfer mechanism attached to the drum.

Thus, after completing ten cycles of the first drum, the second drum (which is

called the tenth drum or 10th drum in English). A spinning wheel. Similarly,

after completing ten cycles of the second drum, one cycle of the third (100th

drum) is completed. Figure (b) shows a rotary counter used in industry (six

digits). It is used to count the number of cycles in its unit time with the

shaft or spindle of continuously rotating low and medium-speed machines. To its

right is a knob resetting the numbers.

Electrical Tachometers

Electrical tachometers operate using electric current or

voltage. There are three types of this.

DC Generator Tachometers

As the name suggests, these tachometers are small DC

generators, commonly used to measure the speed of a rotating machine (such as a

motor, etc.).

Working Principle

This tachometer shows the speed of a rotating machine in

terms of the value of the voltage generated inside it, i.e. the shaft of the

machine whose speed is to be determined is connected to this tachometer. As a

result, the armature of the tachometer is rotated and calibrated at a direct

speed instead of the voltage directly proportional to the speed of the rotating

machine.

Construction and working

The DC generator tachometer is a DC generator with a

permanent magnet. The shaft of its armature (rotating part of DC generator) is

attached to the shaft of this machine. Whose speed is measured.

Due to the permanent magnet, its magnetic field is also

constant. Therefore, if the speed of the armature is low then the low voltage

is produced, and if its speed is high then the output voltage also increases.

The generator is designed in such a way that it produces even a small amount of

voltage at its maximum speed. The speed of a rotating machine is measured by

giving the voltage generated by the jester a millivoltmeter which is directly

calibrated in RPM. Usually, the generator and speed indicator meter are

enclosed in the same shell. The figure shows the internal structure of a DC

generator tachometer.

|

| DC Tachometers |

AC Generator Tachometers

The AC generator tachometer was built because of the

problems found in the DC generator tachometer. So there are solid connections

for the speed indicator. The rotor in the tachometer of the AC generator can be

permanent magnetic or electromagnetic. And the rotor is rotated by touching the

shaft, the speed of which has to be measured. This meter is most popular due to

its accuracy, high efficiency, and extremely low maintenance.

Working Principle

The operation of this tachometer depends on the speed of

rotation of a machine and the amount of voltage generated in it or the

frequency of the input voltage. The speed of measurement is known.

Construction and working

The structure of this tachometer is almost like that of an

AC generator. This tachometer consists of a rotating or rotating magnetic

field. Which is a permanent magnet or electromagnet. What is winded on the coil

coaster? The shaft of the machine whose speed is to be determined is connected

to the rotor of the tachometer. The rotation of the shaft of the rotating

machine rotates the parameters of the tachometer, resulting in the induction of

the stator coil to produce EMF.

Electronic Tachometers

Calibration of the electronic tachometer is easy and output

can be carried far and wide. There are the following types.

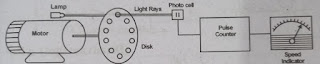

Photo Electric tachometers

A photoelectric tachometer is an instrument in which the

speed of a rotating machine is calculated using an electronic counter in the

form of pulses with the help of light.

Working Principle

The operation of this instrument depends on the

photoelectric effect. Under which when light falls on a photocell, an

alternating voltage is generated in it. The speed of a rotating machine is determined

by measuring them. This light falling on the photocell comes through a

perforated disk attached to the shaft of the rotating machine.

Construction and Working

This tachometer consists of a non-transparent disk. This

disk is mounted on the shaft of a rotating machine, the speed of which has to

be measured. This disk has holes on all sides near the outer edge. At some

distance behind the disc, a small lamp is fitted in the alignment of the holes

in such a way that when the holes come in front of it, its light passes through

the hole and falls on a light sensor on the other side. This light sensor is a

photovoltaic cell.

|

| Electric Tachometers |

Thanks For Reading.